Our Customer-Focus Solutions

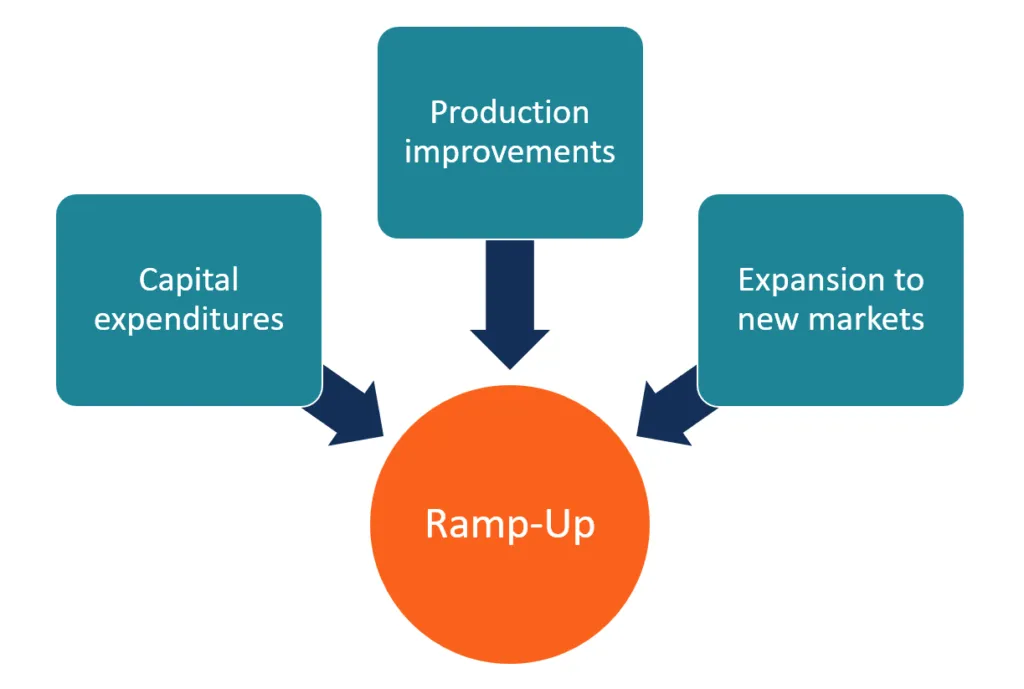

We organize our expertise around your business goals. We provide end-to-end

support to flawlessly launch your product, optimize your operations to boost

productivity, ensure quality, and drive down.

Here’s how we solve your most pressing challenges: